Full coverage: 2017 NPC & CPPCC Sessions

By Belunn Se, Senior industry observer based in Shenzhen, China

On March 5, the 5th session of the 12th National People's Congress opened in Beijing. Premier Li Keqiang delivered the government report during the opening ceremony.

According to the report, China will transform traditional industries: Implement "made in China 2025"; accelerate applications of Big Data, Cloud Computing, Internet of Things(IoT); upgrade traditional industries production, management and marketing model by new technologies and new industry ecosystem and new model; make the development of Intelligent Manufacturing as main direction; promote the construction of national Intelligent Manufacturing demonstration area and manufacturing industry innovation center.

In-depth strategy implementation for the Industry Foundation Enhancement project and Major Equipment Special Project: Develop Advanced Manufacturing industry; promote "Made in China" towards the high-end. Building a Strong manufacturing country.

Big doesn't mean strong

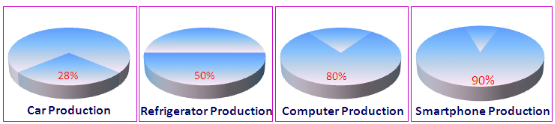

China occupies a large portion of global production in each major segment, 28% of world’s car production, 50% of world's refrigerator production, 80% of world's computer production, and 90% of world’s smart phone production.

Source: STM Statistics

Besides GDP (gross domestic product) growth momentum slowing from high to moderate of below 7% as new normal just as stated in Premier Li's report "The main objective of this year's GDP growth is about 6.5%", resources & energy usage efficiency to be improved, also environment protection plays key role in economic development. China faces other challenges, such as lacking core components and technologies;, rising labor costs, low-skill level, high fluctuation, aging society, and shrinking workforce.

The "de-capacity solidly and effectively", industry restructuring and transformation, enhance the competence from "Big" to "Strong" with Intelligent Manufacturing.

Industrie 4.0 – The Next Generation of Intelligent Manufacturing

Industrie 4.0 should be driven by solid Customer Needs and take the wide range of industry differences into consideration.

Additionally, customization feasibility is related to technology complexity and cost intensity for Product Development and Production in specific industries, to customize clothes or customize a car; also depends on what level of customization level as well, difficulty from easy to hard if just would like to define different color and decorations.

New technologies are accelerating; cooperative robots are working with human operators with max play load of 10kg up to 35kg and can handle vehicle assembly.

Emerging technologies such as: VR/AR have been guided into industry application, also likely Predictive Maintenance based on Cyber Physical System(CPS) and Internet of things (IoT) of cloud computing and Big Data analysis.

While Smart Sensor and Machine Vision getting more advanced, it will enhance industry robots' capacity, such as adding human eyes and touching capacity, they can do more, which include replacing human jobs soon.

Thanks to Artificial Intelligence development, we can expect to see Quantum computing, Neural Processing Unit (NPU) and Deep Learning, just like adding human thinking and learning capacity to Robots, machines will be intelligent to make their own decisions.

Made in China 2025

The Chinese 13th five-year plan, combining Innovation synergy with Made in China 2025, which emphasizes 2I (Informatisation and Industrialization) Integration as main line, Intelligent Manufacturing as main direction. Via enhancement on 3F (Fundamental material, Fundamental processes, Fundamental components), China eyes to shorten the gap with advanced economic entities especially in High End Equipment Manufacturing and Intellectual Manufacturing.

Meanwhile, China has become one of the world's biggest robotics markets since 2013 already. According to the International Federation of Robotics (IFR), China's robot shipments topped 68,000 sets in 2015, accounting for 27.4% of the global market.

Beijing plans to triple its annual production of domestically made robots used in manufacturing to 800,000 units by 2020. Through Made in China 2025 and development on Fundamental components, home-made core components parts percentage will be increasing as well.

Intelligent Manufacturing Practicing

The Ministry of Industry and Information Technology of the People's Republic China (MIIT) publicly noticed the 94 project cases for Intelligent Manufacturing Special Project of Year 2015 on 3th June, 2015; 63 Pilot Run Intelligent Manufacturing Special Projects for Year 2016 on 4th July 2016.

Qinchuan Machine Tool Group Co., Ltd, undertook one of the intelligent manufacturing project, through which improved the efficiency while saving manpower and cutting costs, as addressed by Long Xingyuan, Chairman and Party Secretary of Qinchuan Machine Tool Group Co., Ltd during a Summit.

Lesson learned from the pilot project for Intelligent Manufacturing implementation procedures:

• Advanced target products with excellent profitability (short ROI) and good market prospects are the premise for Intelligent Manufacturing;

• Lean production, optimizing of the production process is the foundation;

• Project target analysis: What is core problem to be solved? To save manpower, improve efficiency, or improve working conditions?

• Identify the breakthroughs: To seize the key point, grasp the loop where efficient achievement could be made quickly;

• Upgrading from Work Station, Production Line, Workshop to Factory Level, carrying out implementation roadmap;

• Training System Integrators for Intelligent Manufacturing growth.

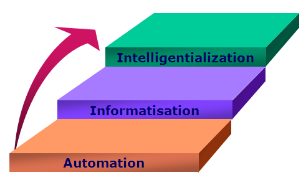

Also consider a sequence from Automation, Informatisation to Intelligentialization step by step:

Moreover, tips when evaluating the manufacturing upgrading:

• Automation: Do not implement Automation with under-developed manufacturing processes;

• Informatisation: Do not proceed with informatisation on poor management;

• Intelligentialization: Do not push intelligentialization without digitization and network;

From Big to Strong

China's latest five-year plan will make billions of Chinese yuan available to manufacturers to incentivize them to upgrade their technologies to advanced machinery and robots.

To embrace the productivity revolution, China can catch up with the leading industrial nations.

China has enacted aggressive national policies and manufacturing goals to bolster growth in the domestic manufacturing industry with pragmatic moves.

Belunn Se, Senior industry observer based in Shenzhen, China

(The opinions expressed here do not necessarily reflect the opinions of Panview or CCTV.com)

Panview offers a new window of understanding the world as well as China through the views, opinions, and analysis of experts. We also welcome outside submissions, so feel free to send in your own editorials to "globalopinion@vip.cntv.cn" for consideration.